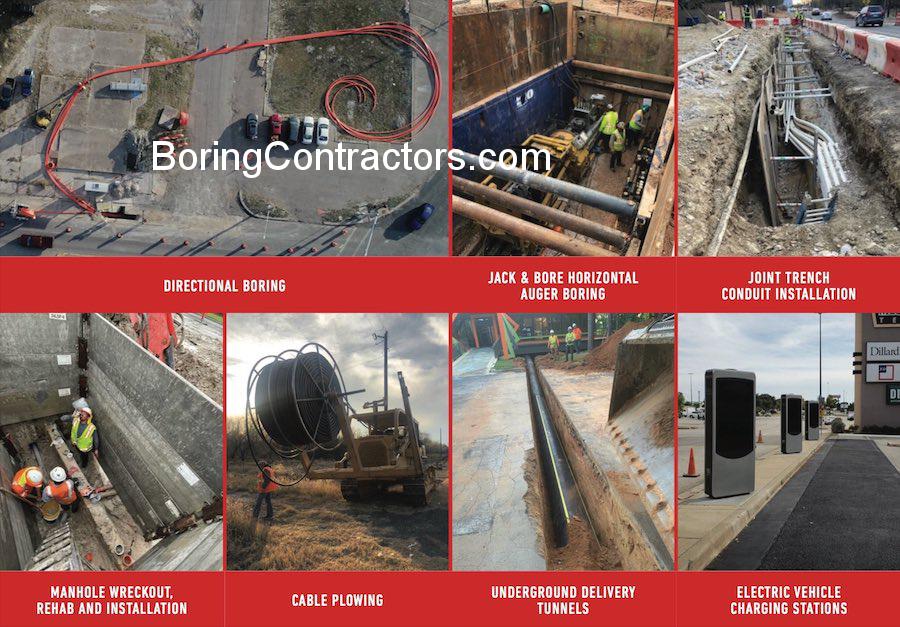

Trenchless Boring

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Trenchless Boring Contractors

Trenchless boring is a crucial technique used across a variety of industries and applications, such as HDD (Horizontal Directional Drilling), directional boring, horizontal auger boring, and jack and bore. Here’s how it is utilized in the specific contexts mentioned:

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Trenchless Boring Companies

Horizontal Directional Drilling (HDD)

- Utilization: HDD employs trenchless boring to install underground utilities by drilling a pilot hole, enlarging it with a reamer, and pulling a product pipe back through the hole.

- Applications: Electric, fiber optics, oil & gas pipelines, water lines, and sewer systems.

- Advantages: Precise, minimizes environmental disruption, and can traverse under obstacles like rivers or roads.

Directional Boring

- Utilization: Directional boring involves steering a bore path to install conduits or pipes with minimal surface disruption.

- Applications: Commonly used for laying fiber optic cables, irrigation pipelines, and utility conduits.

- Advantages: Allows installations over long distances and around curved paths.

Trenchless Techniques

- Utilization: Encompasses various trenchless boring methods like HDD, pipe bursting, and microtunneling.

- Applications: Sewer rehabilitation, gas pipelines, and water systems.

- Advantages: Eliminates the need for extensive excavation, reducing costs and time.

Horizontal Auger Boring

- Utilization: Horizontal auger boring uses a rotating auger inside a casing to remove soil while installing a pipe or casing behind it.

- Applications: Often used for short-distance crossings for sewer and water pipes.

- Advantages: Cost-effective for straight-line bores under roads or railways.

Jack and Bore

- Utilization: Jack and bore uses hydraulic jacks to push a casing through the ground while augers remove the spoil.

- Applications: Sewer systems, water mains, and oil & gas pipelines.

- Advantages: Ideal for short, straight runs under highways or other fixed structures.

Electric and Fiber Optic Installation

- Utilization: Trenchless boring creates precise pathways for conduit systems housing electric cables and fiber optic lines.

- Applications: Data communication networks, power grid expansions, and smart city infrastructure.

- Advantages: Avoids disruption to traffic and surface environments, especially in urban settings.

Sewer Systems

- Utilization: Trenchless methods like pipe bursting or directional boring replace or install sewer pipelines without digging trenches.

- Applications: New installations, repairs, or upgrades of underground sewer systems.

- Advantages: Minimizes disruptions in densely populated or sensitive areas.

Water Lines

- Utilization: HDD and jack and bore methods install water pipelines under existing structures like roads and waterways.

- Applications: Municipal water supply systems, irrigation pipelines, and residential water lines.

- Advantages: Ensures precise placement with minimal ecological and structural impact.

Oil & Gas Pipelines

- Utilization: Trenchless boring, especially HDD, is widely used for installing pipelines over long distances, often under rivers or highways.

- Applications: Transporting oil, natural gas, and other hydrocarbons.

- Advantages: Reduces environmental impact and allows safe installation in challenging terrain.

Irrigation Systems

- Utilization: Directional boring and auger boring install underground irrigation pipelines with precision and efficiency.

- Applications: Agricultural fields, landscaping, and water management systems.

- Advantages: Preserves surface integrity and ensures long-lasting water delivery systems.

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Trenchless Boring Near Me

Conclusion

Trenchless boring revolutionizes underground utility installations by reducing surface disruptions, preserving environmental conditions, and enhancing cost-efficiency. Each method offers unique advantages tailored to the specific needs of electric, fiber, sewer, water, oil & gas, and irrigation applications. These techniques are indispensable for modern infrastructure development and maintenance.