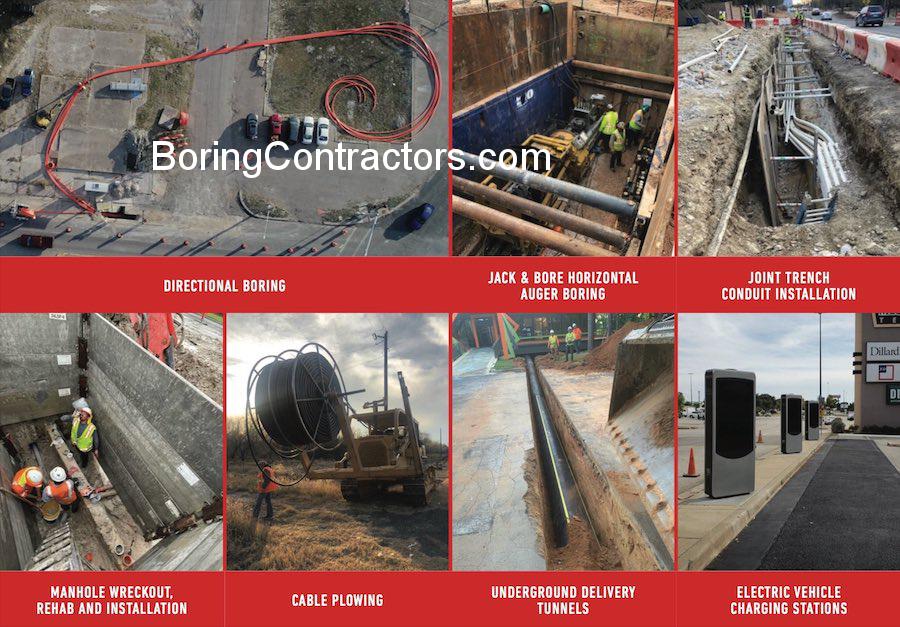

Tunnel Boring

Tunnel Boring in Utility Installations:

Definition: Tunnel boring, also known as tunnel excavation or underground drilling, is a method employed in civil engineering for the creation of tunnels without disturbing the surface above. It involves the use of specialized machinery to bore through various substrates, allowing for the installation of utilities such as electrical, telecommunications, water, sewer, irrigation, and oil and gas pipelines underground.

Utility Types and Top Use Cases for Tunnel Boring:

1. Electrical Utilities: a. Urban Landscapes: In densely populated urban areas, tunnel boring is often utilized to install electrical conduits beneath streets and buildings, minimizing disruption to infrastructure and daily activities. b. Underwater Crossings: For electrical transmission across water bodies, tunnel boring offers a reliable solution for laying cables beneath riverbeds or sea floors, ensuring uninterrupted power supply. c. Mountainous Terrain: Tunnel boring is essential in mountainous regions where traditional trenching methods are impractical due to rugged terrain, allowing for the installation of electrical infrastructure with minimal environmental impact.

2. Telecommunications (FTTB, FTTCS, FTTH & FTTT): a. High-Density Urban Areas: Tunnel boring facilitates the deployment of fiber optic cables for high-speed internet access in densely populated urban centers without disrupting traffic or causing surface disturbances. b. Sensitive Environments: In environmentally sensitive areas such as wildlife reserves or protected landscapes, tunnel boring offers a non-intrusive method for laying telecommunications cables while preserving the ecosystem. c. Cross-City Connectivity: Tunnel boring enables the establishment of interconnected telecommunications networks across cities, enhancing communication infrastructure without disturbing surface activities.

3. Water Utilities (Municipal and Commercial): a. Urban Renewal Projects: Tunnel boring is commonly employed in urban renewal initiatives to upgrade water distribution systems beneath city streets, ensuring reliable water supply without disrupting traffic or causing surface congestion. b. Coastal Areas: In coastal regions prone to erosion or tidal fluctuations, tunnel boring facilitates the installation of water pipelines beneath seabeds, safeguarding water distribution infrastructure against environmental hazards. c. Industrial Zones: Tunnel boring is essential for laying water pipelines in industrial zones where surface activities are intense, providing a secure and efficient means of water distribution for commercial enterprises.

4. Sewer Utilities (Gravity and Force Main): a. Citywide Sewer Upgrades: Tunnel boring is crucial for large-scale sewer system upgrades in urban areas, enabling the installation of new pipelines or the rehabilitation of existing ones with minimal disruption to city life. b. Difficult Terrain: In areas with challenging terrain such as rocky substrates or high groundwater levels, tunnel boring offers a viable solution for sewer pipeline installation, overcoming obstacles that hinder conventional trenching methods. c. Underground River Crossings: Tunnel boring facilitates the construction of sewer pipelines beneath rivers or water bodies, ensuring efficient wastewater management while avoiding surface disturbances and environmental impacts.

5. Irrigation Systems: a. Agricultural Land: Tunnel boring is utilized in agricultural regions to install irrigation pipelines beneath farmland, optimizing water distribution for crop cultivation while preserving arable land. b. Hilly Terrain: In hilly or mountainous areas where surface excavation is challenging, tunnel boring provides a practical solution for laying irrigation channels, facilitating efficient water delivery to crops on sloping terrain. c. Protected Ecosystems: Tunnel boring is employed in environmentally sensitive areas to establish irrigation networks without disrupting fragile ecosystems or disturbing wildlife habitats.

6. Oil and Gas Utilities: a. Pipeline Installations: Tunnel boring is employed in the construction of underground pipelines for oil and gas transportation, ensuring safe and efficient distribution while minimizing surface disturbances and environmental impacts. b. Urban Areas: In densely populated urban environments, tunnel boring offers a cost-effective and non-disruptive method for laying oil and gas pipelines beneath city streets, maintaining energy infrastructure without causing inconvenience to residents. c. Underwater Installations: Tunnel boring enables the installation of oil and gas pipelines beneath water bodies, such as rivers or lakes, ensuring reliable energy supply without the need for disruptive surface activities.