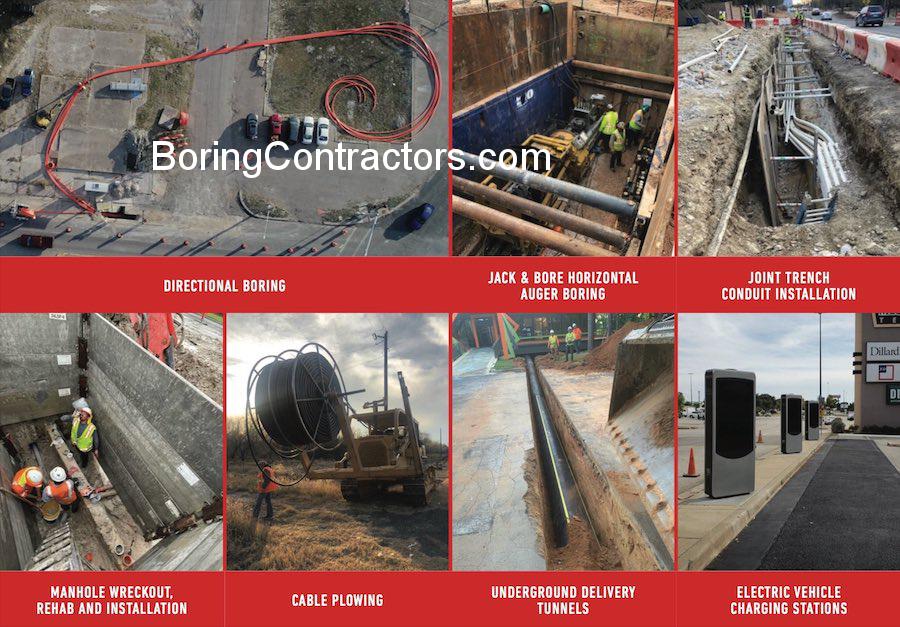

Directional Boring

Directional Boring: Overview

Directional Boring, also known as horizontal directional drilling (HDD), is a trenchless method utilized across various industries for installing underground infrastructure such as pipelines, conduits, cables, and more. This technique minimizes surface disruption and environmental impact by drilling horizontally underground. Here’s how directional boring is employed in different sectors:

Electrical Industry:

- Urban Areas: Directional boring is crucial for installing electrical conduits beneath densely populated urban areas, minimizing disruption to roads, buildings, and other infrastructure.

- Crossing Obstacles: When conventional trenching methods are hindered by obstacles like rivers, highways, or existing structures, directional boring provides a reliable solution for laying electrical cables.

- Sensitive Environments: In environmentally sensitive areas where excavation may cause harm, directional boring allows for the installation of electrical lines without disturbing ecosystems.

Telecommunications Industry (FTTB, FTTCS, FTTH, FTTT):

- High-Speed Connectivity: Directional boring facilitates the installation of fiber optic cables, enabling high-speed internet access in urban, suburban, and rural regions without major disruptions.

- Precision Routing: Telecom companies utilize directional boring to precisely route cables beneath roads, railways, and water bodies, ensuring reliable connectivity while minimizing the risk of damage.

- Cost Efficiency: Compared to traditional trenching methods, directional boring proves more cost-effective for deploying fiber optic networks, particularly in urban environments where surface disruption is undesirable.

Water Industry (Municipal, Commercial, and Residential):

- Pipe Installation: Directional boring is employed for installing water mains and distribution lines in urban, commercial, and residential areas, minimizing disruption to roads, landscaping, and property.

- Access in Confined Spaces: In areas with limited access or restricted space, such as densely built urban environments, directional boring allows for the installation of water pipes without the need for extensive excavation.

- Environmental Sensitivity: Directional boring is preferred in environmentally sensitive locations, such as wetlands or protected areas, where traditional trenching may pose ecological risks.

Sewer Industry (Gravity and Force Main):

- Pipeline Installation: Directional boring is utilized for installing sewer lines, both gravity-fed and force mains, beneath roads, rivers, and other obstacles, reducing surface disruption and environmental impact.

- Urban Redevelopment: In urban redevelopment projects, directional boring facilitates the replacement or expansion of sewer infrastructure without disturbing existing buildings, utilities, or landscaping.

- Emergency Repairs: Directional boring enables rapid and minimally invasive repairs of sewer lines, minimizing downtime and inconvenience to residents and businesses.

Irrigation Industry:

- Precision Agriculture: Directional boring ensures precise installation of irrigation pipelines beneath agricultural fields, minimizing soil disruption and optimizing water distribution for crops.

- Terrain Accessibility: In rugged or uneven terrain, directional boring provides a solution for installing irrigation systems without the need for extensive grading or land preparation.

- Land Conservation: By minimizing surface disturbance, directional boring helps preserve arable land and reduces soil erosion during irrigation system installation.

Oil and Gas Industry:

- Pipeline Installation: Directional boring is employed for laying pipelines in challenging terrains such as mountains, forests, and urban areas, minimizing environmental impact and regulatory challenges.

- Infrastructure Expansion: Directional boring enables the expansion of oil and gas infrastructure while minimizing disruption to existing operations and surrounding communities.

- Resource Protection: By drilling underground, directional boring reduces the risk of surface spills and contamination, enhancing environmental stewardship in oil and gas operations.

Directional boring is a versatile and environmentally friendly method for installing underground infrastructure, offering cost-effective solutions across various industries while minimizing surface disruption and ecological impact.