Horizontal Boring

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Horizontal Boring Contractors

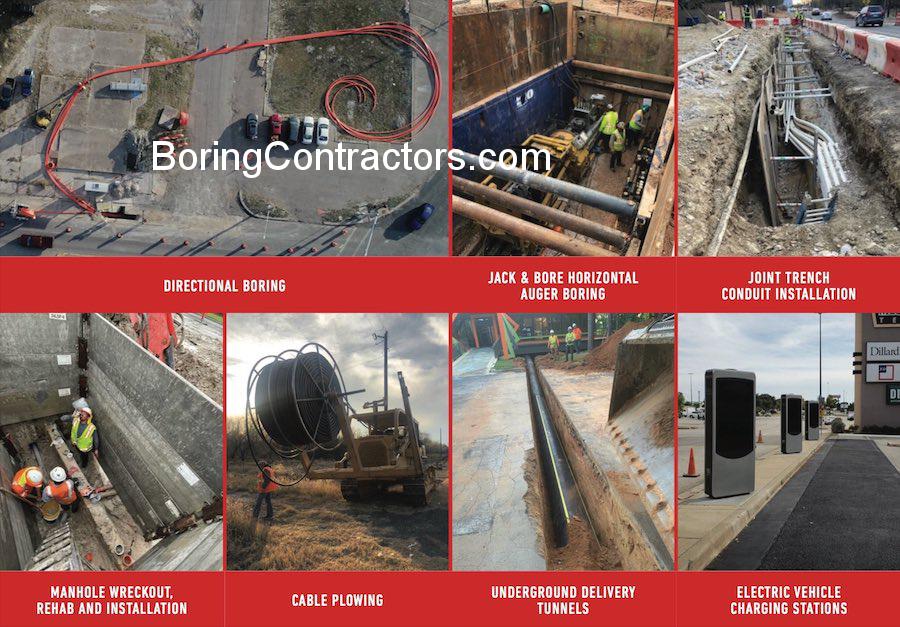

Horizontal boring is a critical technique employed across various industries, allowing for the installation of underground utilities without disrupting the surface. Here’s how it is applied across these specific areas:

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Horizontal Boring Companies

1. Horizontal Auger Boring

- Usage: Horizontal auger boring is widely used for installing pipes, conduits, and casings under roads, railways, and other obstacles.

- Method: A rotating auger inside a steel casing removes soil as the casing is jacked into place. It’s ideal for short to medium distances in stable soils.

- Applications: Sewer, water lines, and smaller-scale oil and gas pipelines.

2. Jack and Bore

- Usage: Often applied for installing larger-diameter steel casings under infrastructure like highways or railways.

- Method: A hydraulic jack pushes a casing pipe while an auger removes soil from within.

- Applications: Sewer and water mains, storm drains, and oil or gas pipelines where precision is critical.

3. Horizontal Directional Drilling (HDD)

- Usage: HDD is the go-to method for installing pipelines over longer distances and in environmentally sensitive areas.

- Method: A drill creates a pilot hole, which is then reamed to the desired diameter. Pipes are pulled through the hole.

- Applications: Fiber optic and electric cables, sewer and water lines, and oil and gas pipelines.

4. Directional Boring

- Usage: This term is often used interchangeably with HDD, particularly in smaller-scale projects.

- Method: Similar to HDD but typically involves shorter distances and smaller diameters.

- Applications: Fiber optic cables, electric lines, and irrigation systems.

5. Trenchless Technology

- Usage: Encompasses all methods of underground construction that avoid surface disruption.

- Method: Includes jack and bore, HDD, and other specialized techniques.

- Applications: Sewer rehabilitation, electric and water line replacements, and new utility installations in urban areas.

6. Electric

- Usage: Horizontal boring is used to install underground electric lines without disturbing roads or landscapes.

- Applications: High-voltage transmission lines, urban power grids, and renewable energy connections.

7. Fiber Optic

- Usage: Fiber optic cables are laid underground using HDD or smaller-scale directional boring.

- Applications: High-speed internet, telecommunications, and smart city infrastructure.

8. Sewer

- Usage: Boring methods are used to install new sewer lines or replace existing ones with minimal disruption.

- Applications: Wastewater infrastructure in urban and suburban areas.

9. Water

- Usage: Horizontal boring is essential for laying water mains and service lines under roads and rivers.

- Applications: Municipal water systems, rural water lines, and irrigation projects.

10. Oil & Gas

- Usage: Critical for pipeline installation in environmentally sensitive and hard-to-reach areas.

- Applications: Long-distance transmission pipelines, gathering lines, and offshore drilling connections.

11. Irrigation

- Usage: Horizontal boring enables the installation of water supply lines for agricultural and landscaping systems.

- Applications: Farms, golf courses, and urban irrigation systems.

Boring Contractors, LLC | The Trenchless Underground Utility Horizontal Directional Drilling (HDD) Company - Horizontal Boring Near Me

Horizontal boring methods offer a versatile, cost-effective, and minimally invasive solution for underground construction, making them indispensable across industries.