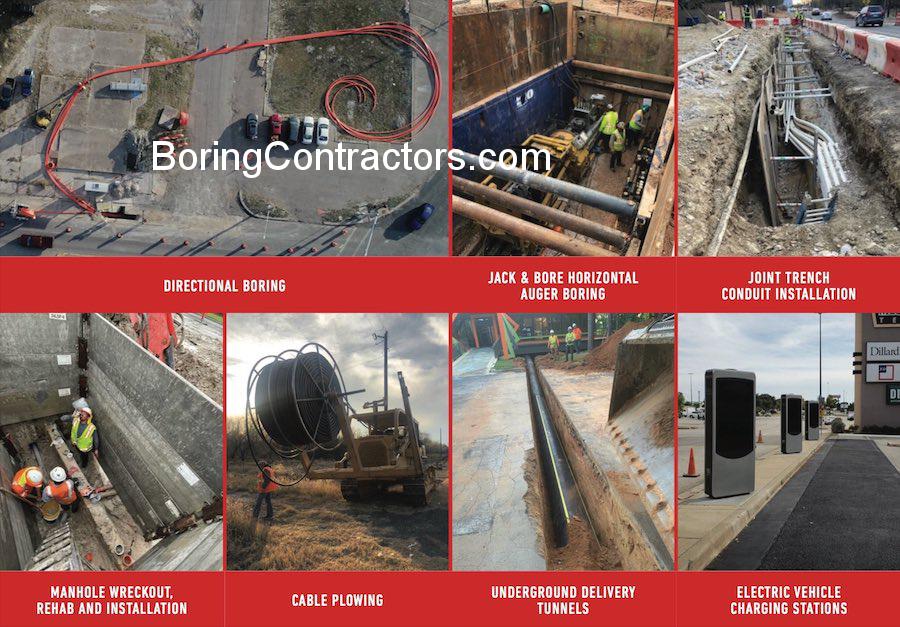

Manhole Installation

Installation of Manholes in Utility Construction

Definition: Manholes are vital components installed during the construction of various utility networks, including electrical, telecom, water, sewer, irrigation, and oil and gas systems. These structures serve as access points for maintenance, inspection, and repair of underground utilities.

Installation Process: During utility construction, manholes are strategically placed along the network route at specific intervals. The installation process typically involves the following steps:

- Planning and Design: Engineers assess the utility network layout and determine the locations where manholes are needed based on factors such as accessibility, network layout, and maintenance requirements.

- Excavation: Excavation is carried out at designated locations to create space for the manhole structure. The depth and dimensions of the excavation depend on the utility being installed and the specifications outlined in engineering plans.

- Manhole Placement: The prefabricated manhole structure is carefully lowered into the excavation. This structure consists of a cylindrical shaft with precast or poured concrete walls and a removable cover at street level.

- Backfilling and Compaction: Once the manhole is in place, the surrounding area is backfilled with suitable material, such as gravel or compacted soil, to provide support and stability. Proper compaction ensures the integrity of the backfilled area and prevents settlement.

- Utility Connection: Utility lines, such as electrical cables, fiber optic cables, water pipes, sewer pipes, irrigation lines, or oil and gas pipelines, are connected to the manhole to integrate them into the network.

- Cover Installation: A heavy-duty cover is placed over the manhole opening at street level to provide protection and secure access. The cover may be made of cast iron, steel, or composite materials and is designed to withstand traffic loads and environmental conditions.

Top Use Cases:

Electrical Industry:

- Cable Maintenance: Manholes provide access for inspecting and maintaining underground electrical cables, ensuring uninterrupted power distribution.

- Transformer Installation: They are essential for installing and accessing transformers, which step voltage up or down along electrical distribution networks.

- Substation Access: Manholes allow for safe access to underground substations for maintenance and equipment servicing, ensuring the reliability of the electrical grid.

Telecom Industry (FTTB, FTTCS, FTTH & FTTT):

- Fiber Optic Cable Deployment: Manholes facilitate the deployment and splicing of fiber optic cables, supporting high-speed internet and telecommunications services.

- Network Expansion: They enable the expansion and upgrading of telecom infrastructure to meet growing demand for bandwidth and connectivity.

- Signal Testing and Troubleshooting: Manholes provide access for testing signal quality, troubleshooting network issues, and performing maintenance tasks to ensure optimal performance.

Water Industry (Municipal and Commercial):

- Water Main Installation and Maintenance: Manholes are crucial for installing and maintaining underground water mains, ensuring reliable water supply to communities and businesses.

- Valve Access: They provide access points for installing and operating valves along water distribution networks, facilitating flow control and system maintenance.

- Hydrant Installation: Manholes enable the installation of fire hydrants, essential for firefighting and emergency water supply.

Sewer Industry (Gravity and Force Main):

- Pipeline Inspection and Cleaning: Manholes serve as access points for inspecting sewer pipelines, performing maintenance, and cleaning to prevent blockages and ensure proper wastewater flow.

- Interceptor Installation: They allow for the installation of sewer interceptors, which capture and remove pollutants from wastewater before it enters the sewer system, protecting water quality and the environment.

- Overflow Control: Manholes are equipped with overflow structures to control sewer overflow during heavy rainfall or peak usage, minimizing the risk of flooding and environmental contamination.

Irrigation Industry:

- Distribution System Installation: Manholes facilitate the installation of underground irrigation distribution systems, ensuring efficient water delivery to crops, landscapes, and green spaces.

- Valve and Pump Access: They provide access points for installing and maintaining irrigation control valves and pumps, allowing for precise water management and system operation.

- Water Conservation Measures: Manholes support the implementation of water conservation measures by enabling the installation of irrigation sensors, meters, and monitoring equipment to optimize water use and minimize waste.

Oil and Gas Industry:

- Pipeline Construction and Inspection: Manholes are used during the construction of oil and gas pipelines to provide access for inspection, testing, and monitoring of pipeline integrity.

- Pressure Regulation and Monitoring: They facilitate the installation of pressure regulating equipment and monitoring devices along oil and gas pipelines, ensuring safe and efficient operation.

- Emergency Response: Manholes serve as access points for emergency response teams to quickly access and mitigate spills, leaks, or other incidents along oil and gas pipelines, minimizing environmental damage and public safety risks.

Manholes play a critical role in the construction and maintenance of utility networks, providing essential access points for ensuring the reliability, safety, and efficiency of electrical, telecom, water, sewer, irrigation, and oil and gas infrastructure.